E-TEST DUST (for the electrotechnical products)

Summary

E-Test Dusts are used for the environmental tests of the electrotechnical products.

APPIE distributes E-Test Dusts which are based on IEC 60068-2-68.

* IEC 60068-2-68 : Environmental testing – Part 2-68 : Tests – Test L: Dust and sand

E-Talc Dust Powder

Material: Talc

particle density : 2.8∼3.0 g/cm3

Chemical component

| Chemical component | % ( weight ) |

|---|---|

| SiO2 | 60∼63 |

| Fe2O3 | 0∼3 |

| AI2O3 | 0∼3 |

| CaO | 0∼2 |

| MgO | 30∼34 |

| Ignition Loss | 3∼7 |

Particle size distribution

Top size: Sieving

Particle size distribution : Laser diffraction–scattering method

| E-Talc Dust Powder | |

|---|---|

| Top size : 75μm over size 1 % or less (weight) | |

| Particle size distribution | |

| Particle size (µm) | under size % (volume) |

| 62 | 96±4 |

| 40 | 91±7 |

| 20 | 58±10 |

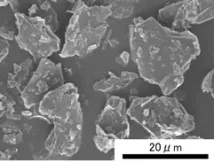

Electron Microscopic Photograph

E-Talc Dust Powder (ETDP)

E-Quartz Dust Fine

Material: Quartz

particle density : 2.6∼2.8 g/cm3

Chemical component

| Chemical component | % ( weight ) |

|---|---|

| SiO2 | 95.5 (min.) |

| AI2O3 | 0.03 (max.) |

| Fe2O3 | 0.13 (max.) |

Particle size distribution

Top size: Sieving

Particle size distribution : Laser diffraction–scattering method

| E- Quartz Dust Fine | |

|---|---|

| Top size : 75μm over size 1 % or less (weight) | |

| Particle size distribution | |

| Particle size (µm) | under size % (volume) |

| 40 | 87±7 |

| 20 | 64±6 |

| 10 | 42±6 |

| 5 | 25±5 |

| 2 | 10±4 |

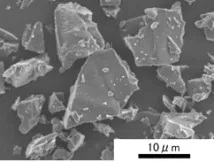

Electron Microscopic Photograph

E-Quartz Dust Fine (EQDF)

E-Quartz Dust Coarse

Material: Quartz

particle density : 2.6∼2.8 g/cm3

Chemical component

| Chemical component | % ( weight ) |

|---|---|

| SiO2 | 95.5 (min.) |

| AI2O3 | 0.03 (max.) |

| Fe2O3 | 0.13 (max.) |

Particle size distribution

Top size: Sieving

Particle size distribution : Laser diffraction–scattering method

| E- Quartz Dust Coarse | |

|---|---|

| Top size : 150μm over size 1 % or less | |

| Distribution | |

| Particle size (µm) | under size % ( weight ) |

| 105 | 79±9 |

| 74 | 60±8 |

| 40 | 36±8 |

| 20 | 24±8 |

| 10 | 15±7 |

| 5 | 9±5 |

| 2 | 3.5±2.5 |

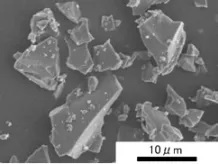

Electron Microscopic Photograph

E-Quartz Dust Coarse (EQDC)

E-Quartz Dust Sand

Material: Quartz

particle density : 2.6∼2.8 g/cm3

Chemical component

| Chemical component | % ( weight ) |

|---|---|

| SiO2 | 95.5 (min.) |

| AI2O3 | 0.03 (max.) |

| Fe2O3 | 0.13 (max.) |

Particle size distribution

Top size: Sieving

Particle size distribution : Laser diffraction–scattering method

| E- Quartz Dust Sand | |

|---|---|

| Top size : 850μm over size 1 % or less | |

| Distribution | |

| Particle size (µm) | under size % ( weight ) |

| 592 | 95.5±3.5 |

| 419 | 77±13 |

| 296 | 32±12 |

| 209 | 12±6 |

| 148 | 8±4 |

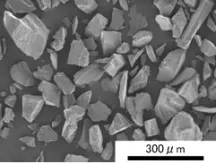

Electron Microscopic Photograph

E-Quartz Dust Sand (EQDS)

Product Price

| Classification | Package (kg) | Price ( JPY ) |

|---|---|---|

| E-Talc Dust Powder ( ETDP ) |

2.0 | 12,700 |

| E-Quartz Dust Fine ( EQDF ) |

2.5 | 23,000 |

| E-Quartz Dust Coarse ( EQDC ) |

3.0 | 23,000 |

| E-Quartz Dust Sand ( EQDS ) |

4.5 | 27,800 |

(2023.1.1)

Air-freight charge and handling charge will be indicated in the invoice.